Blava - Healthy spaces

PURIFYING THE AIR THANKS TO ADDITIVE MANUFACTURING.

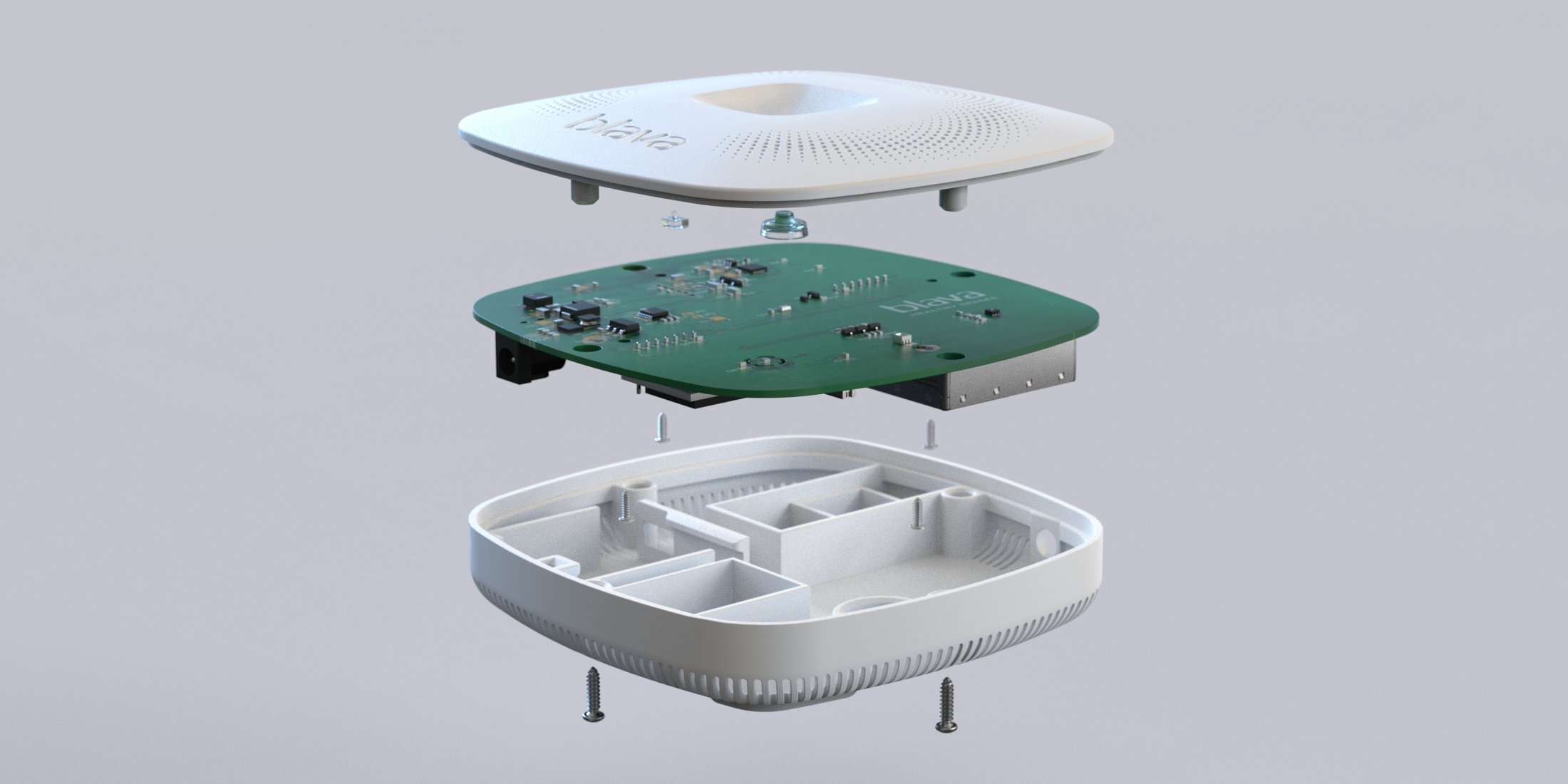

Blava is a cutting-edge device that monitors the air quality in indoor spaces such as offices, rooms, restaurants and cinemas. Our mission was to design a casing that met necessary aesthetic and functional requirements while leveraging the power of additive manufacturing for optimal results.

This approach has significantly reduced the time to market of the product, allowing for rapid scaling and customization based on customer needs. Additive Manufacturing also enables efficient, cost-effective and decentralized production, eliminating the need for large stocks and reducing the carbon footprint.

Throughout the project development, we achieved a quick time to market and launched the product swiftly by leveraging 3D printing technology for both prototyping and final part manufacturing.

Moreover, we developed an MVP to validate different product features and market demands. The advantages of 3D printing enabled us to accomplish these objectives with exceptional speed and efficiency.

Additive manufacturing also allows for adjusting production volume to match incoming requests without the need to invest in expensive injection molds. Furthermore, 3D printing provides the flexibility to make small aesthetic or functional changes or variations without affecting manufacturing costs.

For instance, we can offer a customization and personalization service to our customers, allowing them to include their own logo or even modify the texture of the top surface. Thanks to our use of computational design tools during the product design process, we can easily make such changes without incurring additional manufacturing or design costs.

Vertical

Customer

Year

Healthcare

Healthy Spaces

2.020

Services

Design for additive manufacturing

Computational design

Parametric Design

Product design

Key Words

#MJF #fusion360